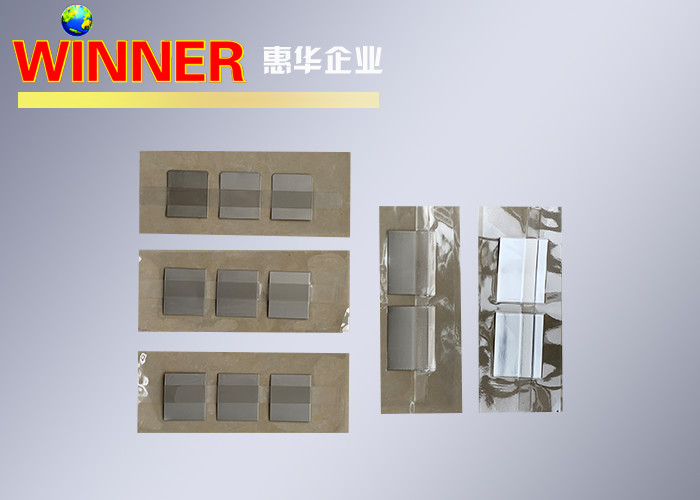

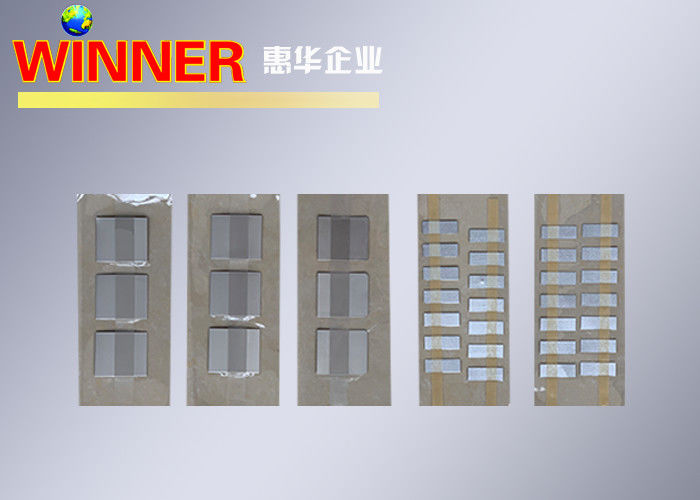

Aluminium tabs/Nickel tabs For Lithium Ion Polymer Battery

【Lithium-ion Battery Tabs】

Battery tabs play an important role in lithium-ion cell manufacturing. A typical large format lithium-ion cell uses copper foil as the anode current collector and aluminum as the cathode current collector. A ‘foil-to-tab’ weld is needed to gather all the current collector plates (foils) inside the cell and join them to a tab which exits the cell casing, allowing the cell’s energy to be transferred to an external source. There are two foil-to-tab welds in each cell, and hundreds of cells in a typical lithium-ion battery pack.

Otherwise We can design lithium-ion battery production line according to customer requirements(For phone battery,digital battery,EV battery,laptop battery, Tablet PC battery,GPS battery and so on) ,and provides a full set of production line equipments,technonogy,material(LiCoO2,Li(NiMnCo)1/3O2,graphite, copper,seperator and so on).Manufacture lithium ion battery?We provide one-stop solution, provide a "turn key" project for you!

【Al-Clad Cu material tab】

The aluminum-clad copper material tab provides a low cost and high-performance solution for li-ion battery tab joining. Nowadays, the leads or tabs from Li-ion pouch and prismatic cells are often configured with one lead of copper and the other lead of aluminum. This brings a challenge for welding copper to aluminum with the busbar. By replacing one of the leads with an aluminum-clad copper tab, the busbar joining can be applied to all aluminum to aluminum connections. This greatly simplifies the welding process.

1.Outward appearance:clean, no scratch, pinhole, burr

2.Tensile strength:more than 75Mpa

3.Elongation:more than 20%

| Specifications |

| Width |

4mm 5mm 8mm 10mm Can be customized |

| Purity |

More than 99.9% |

| Thickness |

0.1mm 0.15mm 0.2mm |

| Application |

Connect to anode/cathode current collector as polymer battery |

| Max. Loading Current |

3A

|

【Advantages】

- Free of additional welding process

- Reducing resistance of anode

- Lower discharge efficiency at low temperature than traditional tab and lead

- Reducing battery heating

- Excellent electrolytic corrosion resistance and breaking resistance

【Packaging & Delivery】

Packaging Details:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging. 2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way. 3 Responsible for the damage during the shipping process, will change the damage part for you for free.

Lead Time :

Quantity(Sets) 1 - 10 >10

Est. Time(days) 7 To be negotiated

【FAQ】

1. Are you trading or manufacturer ?

We are company,and we have our own factory

2. How long is your delivery time?

Generally it is 2-3 days if the goods are in stock. or it is 5-7 days if the goods are not in stock, it is according to quantity.

3. Do you provide samples ? is it free or extra ?

Yes, we could offer the sample for free charge but do not pay the cost of freight.

4. What is your terms of payment ?

Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!